The solid phase is used for fragile materials because it operates at low pressures. Quartz and copper sulphate are abrasive materials that a pressure system will move.ĭilution moves material at great velocity under pressure and there is some breakage during transportation. A pressure system pushes the material through the pipe and can move the abrasive. The vacuum system draws material through the pipeline and is ideal for pressure sensitive non-abrasive materials. Other factors include the number of pickup points and the size of the receiving bin. The size of the system should leave room for maintenance and monitoring. It is important to understand if the system will be able to handle vertical or horizontal spacing. Mass density is the first consideration as it determines the vacuum receiver and the air source. The first consideration when choosing a conveying system is the type of material to be handled. Here are some guiding points to consider when choosing a pneumatic conveyor conveying system. Equipment and methods of transportation must be appropriate for the material being transported. When exploring compressed air systems, as a method of transportation, there are factors that must be considered. Pneumatic conveying is a safe and effective method of transporting materials and is used in many industries. Takes up less floor space so it's easier to locate.

Ability to maintain a controlled atmosphere around the material.

Pneumatic conveying systems are easier to maintain and more cost effective than mechanical conveying systems - fewer moving parts. When the system is enclosed, there is protection against the emission of dust into the atmosphere and also protection of the material being transported from external contaminants. Can run vertically or horizontally over a long distance. The system can be designed as a positive pressure system, a vacuum system (negative pressure system) or a combination of both.ĭue to the compact nature of the pipeline conveying line, pneumatic conveying systems can be routed around existing equipment, providing more flexibility than mechanical conveying systems. This process is easily accomplished by pushing or pulling materials suspended in the air through the velocity of the gas. with products in the system: dilution, dense phase and air conveyance.ĭilution transport is a continuous, high-speed, low-pressure process and has a high air-to-product ratio.

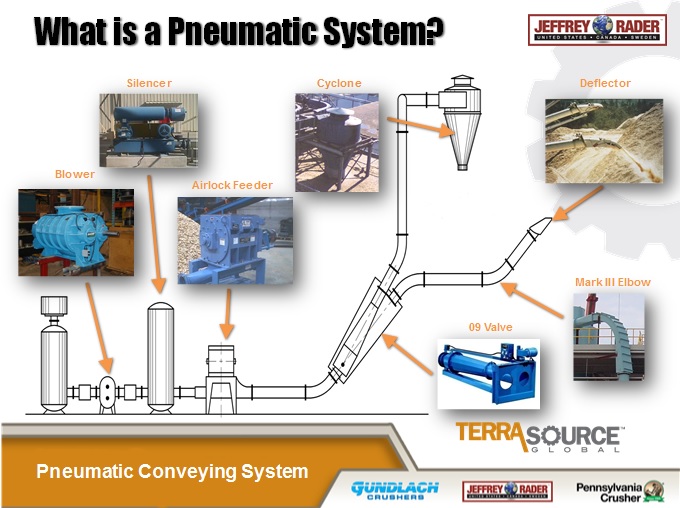

Reduced maintenance, equipment and operating costs compared to mechanical conveyor systems.Īirflows, pressure or vacuum are used to move materials and there are three main types of pneumatic conveying methods that are functionally related and suitable for a particular air velocity, pressure, and ratio. The pneumatic system is an industrial conveyor system that can run vertically or horizontally over long distances and protects against the emission of dust into the atmosphere. Well-designed pneumatic conveyor systems are an economical, practical means of transporting materials from point A to point B, proving to be more efficient than alternative mechanical systems. The flexibility of the pipes of a pneumatic conveying system allows them to be installed in existing spaces, as they can be routed around the unit. Common system components are the material entry point, piping, receiving point, and air flow device, but the specific nature and capacity of the system varies between models. Pneumatic conveying system transfers bulk materials through pipelines. System structure and function of pneumatic conveyor

0 kommentar(er)

0 kommentar(er)